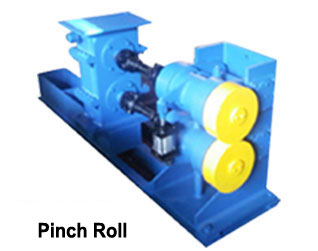

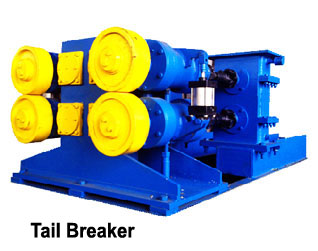

AKSHI ENGINEERS is top notch Cantilever Pinch Roll and Tail Breakers Manufacturers in India during the last decade of the 21st century reading to their widespread use was a great achievement in the field of not only rolling mill rolls but also whole steel rolling industry. We producing High speed Pinch used at completely different location in rolling mill along with before TMT extinction box and when TMT extinction box to produce consistent Tension of the Bar. The use of 2 Hi Gear Box, Solid Rolls with Cardoon Shaft provided in these DC Pinch Rolls helps in achieving uniformity in operations.

| Material | : | M.S. Prime Plate, Graded Cast Iron |

| Base | : | Mild Steel Prime Plate Fabricated |

| Size | : | 205 mm to 360 mm (as per requirement of mill) |

| Barrel Length | : | As Suitable to the Pinch Roll. |

| Chocks | : | Steel Chocks fitted in Pinch Roll for Spherical Roller Bearing |

| Bearing | : | Imported Spherical Roller Bearing |

| Shaft | : | Jointing with Cardon Shaft |

| Gear Box | : | Includes Forged Steel Single Helical Gears with all accessories |